| |

| |

|

|

| |

|

Classic Bridgeport Boss 5 NC knee mill ready for a retrofit! |

|

|

| |

Bridgeport manufactured a large number of "Boss" machines throughout the 70's and 80's. These machines are of high quality and make an excellent choice for a CENTROID CNC retrofit.

There are many other brands of good high quality machines available on the market today for reasonable prices. The original controls have gone past their useful life and the machines themselves have outlived the electronics. Often older NC and CNC machines can be found in excellent mechanical condition. These machines usually have been a nightmare to operate and maintain since the stock control is so outdated. Also, many of these old controls were never really that good to begin with and since the original systems were so difficult and problematic to use it is common to see early NC machines with low hours on them...prime for a CENTROID retrofit.

|

| |

|

|

|

|

Remove the old NC control |

| |

The first step is removing the old NC control from the machine. With a Boss machine this only takes about 30 to 45 minutes. The old Boss 5 control has two cabinets, one on the right and one in the back of the machine. Both are removed reducing the footprint of the machine significantly. |

| |

|

| |

|

|

| |

|

Mount the new CENTROID CNC control cabinet |

|

|

| |

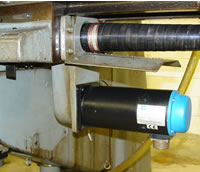

Next mount the new CENTROID CNC control cabinet to the back of the machine. The bottom bracket uses two existing mounting holes. As you can see the CENTROID retrofit kit comes completely assembled ready to install right out of the box! The large black flexi-conduit connects to the operators console. The coiled cables on the floor are all factory prewired ready to hookup to the spindle,lube pump, flood pump, mister, speed up/dn, spindle brake, X,Y,Z axis motors and limit switches. No other kit is so complete. All the cables are labeled and clearly indicated on the hookup schematic. |

| |

|

|

|

|

Remove the old stepper motors |

| |

Since this is a Boss 5 which used big, old, hot and noisy stepper motors we will be replacing the axis motors with new CENTROID 29 in-lb DC servo motors.(continuous torque rating click here for more info on torque ratings) So now, simply unbolt the stock motors and retain all the hardware.

|

| |

|

| |

|

|

|

|

To mount the new CENTROID servo motors we will be reusing the existing belts, pulleys and hardware. The new CENTROID servo motor is a direct bolt up! what could be easier? |

| |

|

|

| |

|

Mount the new Servo motor |

|

|

| |

The CENTROID servo motor is over 2 times as powerful and twice as fast as the old stepper motor it replaces and more importantly it has a resolution that is over 8 times that of the old motor AND the new motor is closed loop unlike the old stepper motor so, it never loses position.

Once the motors are mounted simply screw on the cable coming from the control onto the cannon connector located on the motor. It is keyed so it only goes on one way.

|

| |

|

| |

|

|

|

|

Mount the operators console |

| |

|

| |

Mounting the console is quick and simple, all the brackets and hardware are supplied with a CENTROID retrofit kit. We simply drilled and tapped 4 holes and bolted the supplied bracket onto the side of the ram. Then we install the center pin for the hinge at both ends and hung the operators console. Once the console was hung, we simply connected the flexi-conduit to that runs from the console to the control magnetics cabinet. |

| |

|

| |

|

|

| |

|

Power up and checkout. |

|

|

| |

Now there are only a few things to finish connecting such as the power cables for the accessories and then we are ready to power up and proceed with the control configuration and check out. Since we have used a complete CENTROID CNC kit with new motors and all new control electronics this machine is not limited in any way by the technology originally used. It is now a much more capable machine and much more reliable and user friendly. It is now compatible with modern computer equipment and programs and is software updateable, unlike the old control which sealed its doom. |

| |

|

| |

|

|

| |

|

Machine parts not possible with the original control. |

|

|

| |

Not only did we revive this great machine we added CNC capabilities that were never possible with the old control.

- True 3 axis machining with high speed processing. (no hesitation)

- 2D and 3D Digitizing

- Color graphics: while programming, while machining.

- Stop and restart job at any point.

- Remembers part zero positions if power is removed or E-stop

- Remembers part programs and tool librarys

- Automatic tool height measurement

- Built in Hard drive and ethernet LAN ready, USB port.

- Conversational programming.

- Graph and Edit G-codes from any source at the control.

|